Assessment Report

方案Scheme

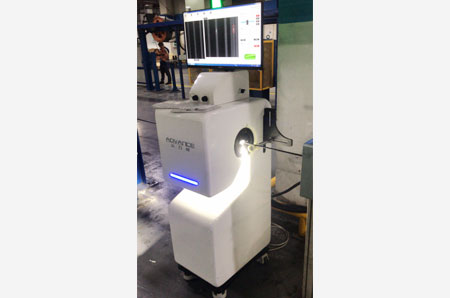

管材表面缺陷CCD检测系统

CCD detection system for surface defects of cable

1? 管材表面缺陷检测仪能够采集?显示和分析管材产品表面杂质缺陷每一平方毫米的工具?这是目前检测表面缺的方法?表面缺陷检测器记录缺陷位置以及保存缺陷图片?操作员可以通过使用表面缺陷检测器来查看当前表面图片,最近一次的表面缺陷图片以及缺陷尺寸?工程和生产监督人员还可以通过表面缺陷检测器来检查缺陷,而无需去查看缺陷本身,并且根据生产批号,导出报表?使用尖刀视智能科技表面缺陷检测器,您可确保发送给您客户的产品符合高标准要求,准确提高产品质量?

Wire cable surface detector is the only tool that is able to collect, display and analyze each square millimeter on the surface of product. The analyzed content covers: surface of cable sheath, conduit, pipe fittings, rod and hydrosoluble adhesive tape. This is the most thorough approach to detection of surface defects at present. The surface defect detector records defect position and stores defects picture. The operator can see picture of current surface, latest surface defect picture and defect size by surface defect detector. The engineering and manufacturing supervision personnel can further detect defects by dint of surface defect detector without need to check the defect itself, and can export report according to manufacturing batch number. Advance intelligent scientific surface defect detector enables you to guarantee the products delivered to customers meet high standard and improve the quality of products accurately and efficiently.

2? 杂质检测结果Detection result

管材表面缺陷检测是采用3条互成120度的视觉投影,可以无盲区的检测到产品的细小缺陷,即使缺陷很小而且高速也能检测到;同时具有系统软件管理与数据分析功能?

Adopting three visual projections which form 120 degrees between each other, detection of surface defects of wire cable can detect products' fine defects without dead zones, even the very small and rapidly moving ones. The detecting of letter quality of wire cable characters is realized via analysis on OCR character recognition on video, also is provided with system software management and data analysis.

2.1?管材表面缺陷检测Detection for surface defects of wire cable

1)?杂质、脱料?划伤破裂?突出的皮层?斑点凸起?凹陷?叠接等缺陷,

Stripping, scratching and rupturing, protrudent skin layer, bulging spot, recession, overlapping, etc.

2)?管材变细,变粗等,Wire cable thins or thickens, etc.

3)?灵敏度参数可调?Adjustable sensitivity parameter

a?测量设备在一个轴向上的结构, 这种结构可以有效保证测量结果的准确性?Following schematic diagram shows the structure of measurement equipment in one axial direction. This structure can efficiently guarantee accuracy of measurement result.

b?以下示意图表示了测量设备在三个轴向上的结构?采用三个维度的检测结构, 这种结构可以有效保证测量结果的准确性?

Following schematic diagram shows the structure of measurement equipment in three axial directions. This detection structure of three dimensions can efficiently guarantee accuracy of measurement result.

在管材的外观缺陷检测中,采用3条互成120度,可以无盲区的检测到产品的细小缺陷,即使缺陷小而且高速也能检测到?

In detection of appearance defects for wire cable, three visual projects which form 120 degrees between each other are adopted to detect the find defects of products, even very small and rapidly moving ones.

c?以下示意图表示了测量设备的检测特征?对于产品的特征缺陷特征,特别是缺陷较小不是非常明显是,基本能实现”零缺陷”,可以有效保证产品质量的准确性和精确度?

Following schematic diagram shows detection features of measurement equipment. "Zero defects" can basically be realized to effectively guarantee products’ accuracy and precision especially when the defects are very small and insignificant.

d.测量设备的技术参数Technical parameters of measurement equipment

检测方向:3

Detection direction:3

检测方式:非接触式连续测量Detection mode: non-contact continuous measurement

检测精度:0.002-0.999mm 灵敏度设定值的±1%

Detection precision:0.002-0.999mm ±1% of set value of sensitivity

检测速度:0M/Min-400M/Min

Detection velocity:0M/Min-400M/Min

警报输出:红色LED亮,报警常开接点闭合

Alarm output: when red LED is on, normally open contact of alarm is closed

报警时间:0.1sAlarm time: 0.1s

使用温度:-5℃- +55℃

Service temperature:- 5℃- +55℃

功耗:10~20W

Power consumption: 10-20w

健康Health

Led 的亮度低于500 流明,在密闭的环境下对操作员的视觉没有伤害?

The brightness of Led is lower than 500lm, and does not hurt vision of operator in enclosed environment

噪音低于 60 分贝?

Noise is lower than 60db

安全 Security

设备边缘平整,没有潜在尖角伤及操作员工?

Equipment has leveled edge without potential sharp corner to hurt the operator

设备任何危险部分有明显标识?

All dangerous parts of equipment have obvious identifications.

环境Environment

气体 Gas:N/A 液体Liquid:N/A 固体Solid:N/A

Copyright Instruction

*版权说明*

此设计规格书版权归尖刀视所有,仅供双方研发合作使用,双方应共同对此设计规格书承担保密责任?

This design specification has copyright reserved and is only for R&D and cooperation by both parties, who should keep it confidential.

推荐资讯

- 2016-07-11 谷歌的DeepMind与NHS合作用机器学习来与失明作斗争

- 2016-01-11 人工智能的发展

- 2016-12-13 江苏注塑机模具保护器好用吗?

- 2015-06-02 机器视觉概述

- 2015-12-24 机器视觉,机器看懂世界

- 2018-09-16 线缆缺陷检测

- 2016-12-13 模具监视器产品操作技术流程

- 2015-12-24 机器视觉系统与人类视觉的差异

- 2016-07-08 机器视觉让机器看懂世界 未来发展潜力巨大

- 2015-08-09 尖刀视智能申博士:机器人时代男性失业的可能远超女性

- 2015-06-03 尖刀视机器视觉的工作原理介绍

- 2015-08-19 未来电子制造业离不开机器视觉

- 2015-06-02 中国制造2025下的尖刀视智能业绩突飞猛进

- 2016-01-12 机器视觉技术的检测对企业的发展

- 2015-06-29 中天科技

- 2015-06-03 德国马牌

- 2018-09-16 光缆缺陷检测

- 2016-12-05 芯片级嵌入式模具保护器未来发展的行业趋势

- 2015-08-03 机器视觉推动行业质量

- 2015-06-02 机器视觉应用实例

联系尖刀视Contact

Mail: rd@jiandaoshi.com

地址:上海闵行区新骏环路189

号漕河泾高科技园B座3层4层